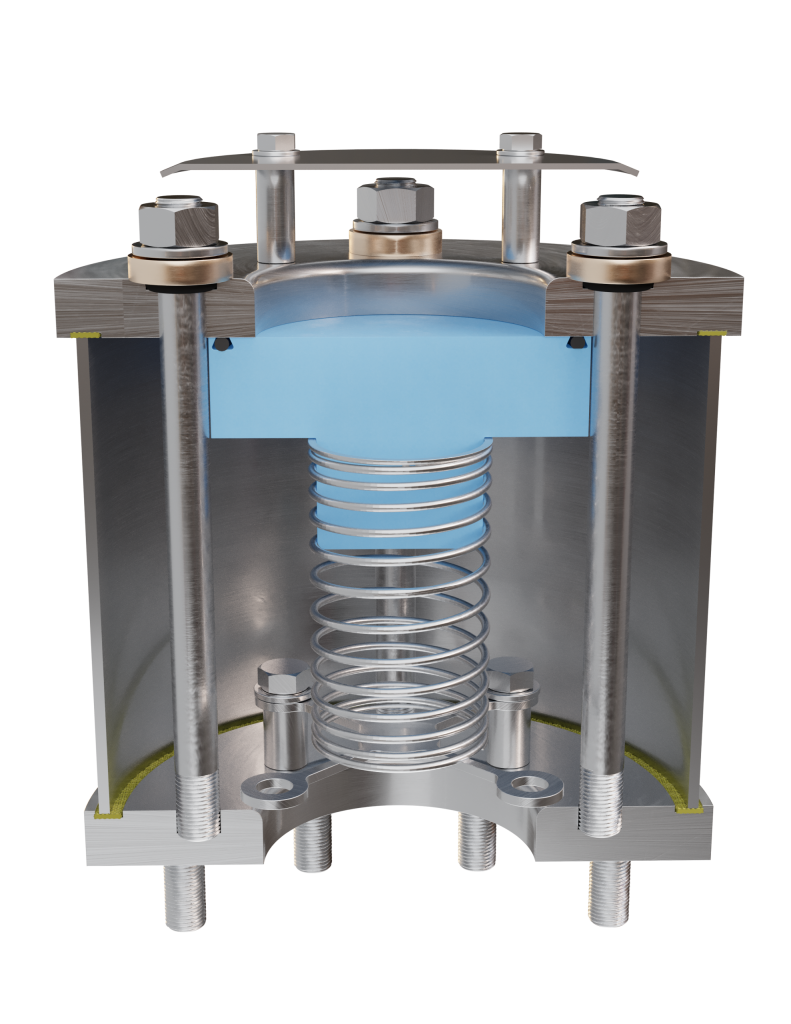

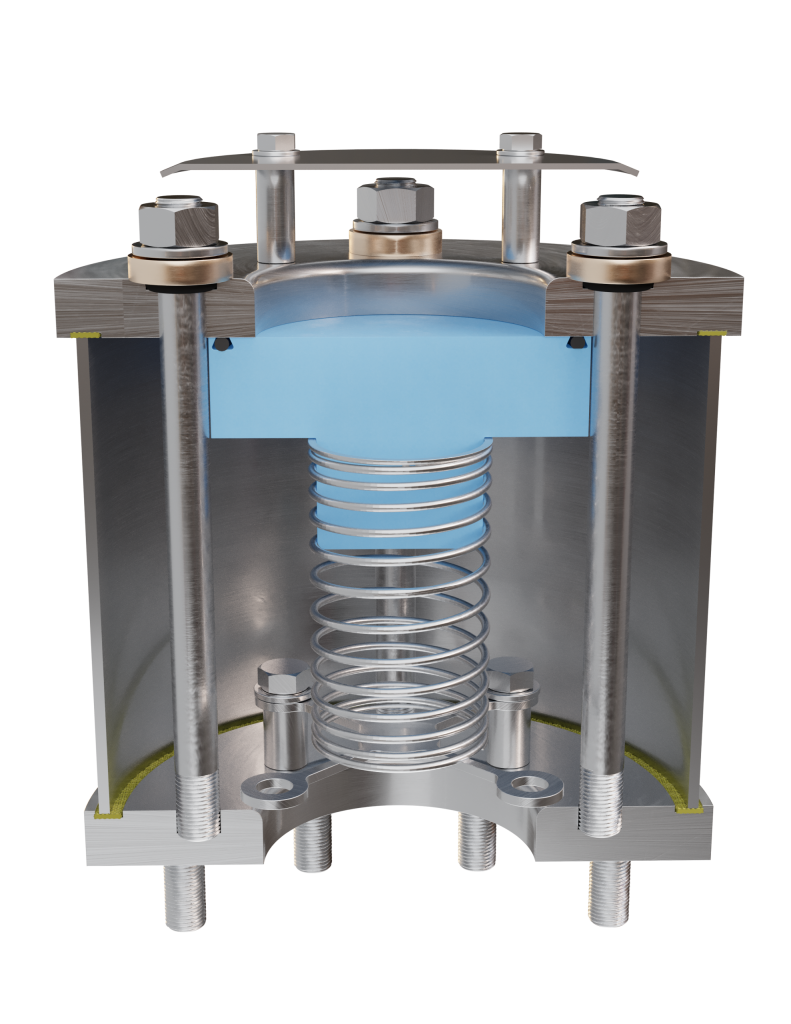

Variant combination air release and vacuum break valves safeguard pipelines from harmful vacuum conditions, whilst preserving system efficiency. The integral antishock mechanism provides additional protection against damaging surges caused by uncontrolled filling or pump stopages.

The primary role of air valves is to admit air into pipelines to prevent damaging negative pressures that can arise under conditions such as:

• Isolation

• Interruption of supply

• Scouring

• Negative pressures during surge events.

Variant air valves provide a full-bore, unobstructed flow path that maximizes air in-take capacity.

• Potable water

• Settled Raw Water

• High-capacity air intake

• Optimum flow characteristics

• 1 KPa low pressure sealing

• Compact design

• No dissimilar metal corrosion.

• Stainless steel cover screen

• ¼ inch bleed port with plug

Correct sizing of air valves primarily depends on intake requirements under vacuum conditions. To safeguard pipelines and joints, it is key to limit negative pressures to a maximum of 35 kPa. This is achieved by ensuring sufficient airflow into the pipeline when vacuum conditions occur.

Valve sizing calculations must account for:

• Pipeline diameter

• Gradient

• Rupture percentage

• Scour valve sizes

After determining these parameters and calculating the required intake flow rates, the appropriate air valve size can be selected.

• Body: 304/316 Stainless Steel.

• Kinetic float: High-Density Polyethylene.

• Vacuum seal: Nitrile/EPDM

• Spacers, tie rods, bolts, nuts and washers: 304/316 Stainless Steel.

• Cover: 304 /316 Stainless Steel

• O-ring spacers: Brass.

• O-rings: Nitrile/EPDM

• Hydrostatic test at 1.5 times rated working pressure

• Low-pressure sealing – 1 kPa

• Threaded valves – Male BSP/NPT

• Flanged valves – studded

• 4°C to 75°C